Introduction to Global Supply Chain Disruptions

Definition and Overview

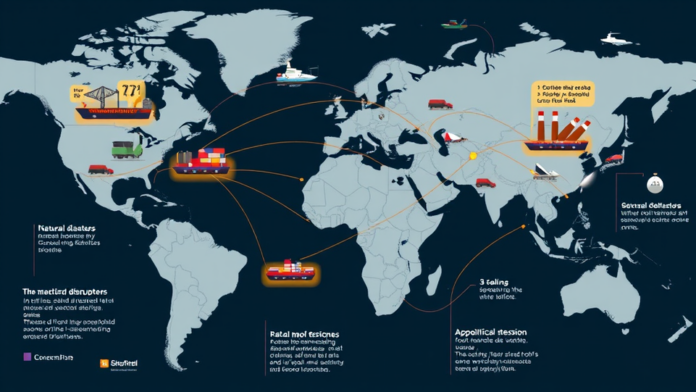

Global supply chain disruptions refer to significant interruptions in the flow of goods and services across international borders. These disruptions can arise from various factors, including natural disasters, geopolitical tensions, and pandemics. Such events can lead to delays, increased costs, and inventory shortages. Businesses must adapt quickly to these challenges. It’s crucixl to stay informed. Understanding these dynamics is essential for effective risk management. Every business should prepare for uncertainties.

Historical Context and Recent Trends

Historically, supply chain disruptions have been influenced by events such as wars, economic crises, and technological changes. These factors have shaped the way businesses operate globally. Recent trends indicate an increase in frequency and severity of disruptions. This is concerning for many industries. He must consider these risks seriously. Understanding past events can guide future strategies. Knowledge is power in this context.

Causes of Supply Chain Disruptions

Natural Disasters and Climate Change

Natural disasters and climate change significantly impact supply chains. Events such as hurricanes, floods, and wildfires disrupt logistics and production. These disruptions can lead to increased costs and reduced availability of goods. He must assess these risks carefully. Additionally, climate change exacerbates these issues through unpredictable weather patterns. This unpredictability complicates planning and forecasting. Businesses should prioritize risk management strategies. Preparedness is essential for resilience.

Geopolitical Tensions and Trade Policies

Geopolitical tensions and trade policies can severely disrupt supply chains. Tariffs, sanctions, and trade agreements influence the flow of goods. These factors create uncertainty in international markets. He must navigate these complexities strategically. Additionally, political instability can lead to sudden supply shortages. This unpredictability affects pricing and availability. Businesses should monitor geopolitical developments closely. Awareness is crucial for informed decision-making.

Impact on Businesses

Operational Challenges

Operational challenges significantly affect businesses’ efficiency and profitability. Disruptions can lead to delays in production and delivery. This results in lost revenue and dissatisfied customers. He must address these issues proactively. Furthermore, increased operational costs can strain financial resources. Companies should implement robust contingency plans. Preparedness can mitigate potential losses. Every business needs a strategic approach.

Financial Implications

Financial implications of supply chain disruptions can be significant. Increased costs may arise from delays and inefficiencies. This can lead to reduced profit margins. He must analyze these impacts carefully. Additionally, cash flow issues may emerge due to inventory shortages. Businesses should prioritize financial forecasting. Accurate predictions are essential for stability. Every decision counts in this environment.

Sector-Specific Effects

Manufacturing and Production

Manufacturing and production sectors face unique challenges during disruptions. Supply shortages can halt production lines, leading to significant delays. He must evaluate the impact on output levels. Additionally, increased costs for raw materials can erode profit margins. This situation requires strategic sourcing decisions. Companies should consider alternative suppliers. Flexibility is key in this volatile environment. Every choice affects overall efficiency.

Retail and Consumer Goods

Retail and consumer goods sectors experience distinct impacts from supply chain disruptions. Inventory shortages put up lead to stockouts, affecting sales and customer satisfaction. He must monitor inventory levels closely. Additionally, fluctuating prices for goods can alter consumer purchasing behavior. This volatility requires agile pricing strategies. Companies should enhance their demand forecasting capabilities. Accurate predictions can mitigate potential losses. Every decision influences customer loyalty.

Strategies for Mitigating Risks

Diversification of Supply Sources

Diversification of supply sources is essential for risk mitigation. By sourcing from multiple suppliers, businesses can reduce dependency on a single source. This strategy enhances resilience against disruptions. He must evaluate supplier reliability regularly. Additionally, exploring alternative geographic regions can minimize risks associated with local events. Companies should conduct thorough market analysis. Informed decisions lead to better outcomes. Every choice strengthens supply chain stability.

Investment in Technology and Automation

Investment in technology and automation is crucial for mitigating risks. Advanced systems can enhance operational efficiency and reduce human error. This leads to cost savings and improved productivity. He must assess the return on investment carefully. Additionally, automation can provide real-time data for better decision-making. Companies should prioritize integrating innovative solutions. Staying competitive requires continuous improvement. Every investment should align with strategic goals.

Financial Planning in Uncertain Times

Budgeting for Supply Chain Resilience

Budgeting for supply chain resilience requires careful financial planning. Allocating resources for unexpected disruptions is essential. This approach helps maintain operational continuity. He must prioritize flexibility in budget allocations. Additionally, scenario planning can identify potential risks and costs. Businesses should regularly review their financial strategies. Adaptability is key in uncertain environments. Every decision impacts long-term stability.

Scenario Analysis and Contingency Planning

Scenario analysis and contingency planning are vital for effective financial management. By evaluating various potential outcomes, businesses can prepare for uncertainties. This proactive approach minimizes risks associated with supply chain disruptions. He must identify critical variables that impact operations. Additionally, developing contingency plans ensures swift responses to unexpected events. Companies should regularly update their analyses. Flexibility is essential in dynamic markets. Every strategy should enhance resilience and adaptability.

Future Outlook and Recommendations

Emerging Trends in Supply Chain Management

Emerging trends in supply chain management indicate a shift towards greater transparency and sustainability. Companies are increasingly adopting digital technologies to enhance visibility. This allows for better tracking of goods and resources. He must embrace these innovations to remain competitive. Additionally, collaboration among supply chain partners is becoming essential. Strong partnerships can lead to improved efficiency. Every business should prioritize adaptability and innovation.

Best Practices for Businesses Moving Forward

Best practices for businesses include investing in technology and enhancing supply chain visibility. By leveraging data analytics, companies can make informed decisions. This leads to improved operational efficiency. He must focus on building strong supplier relationships. Additionally, adopting sustainable practices can enhance brand reputation. Companies should regularly assess their risk management strategies. Every action should align witn long-term goals.