Introduction to Global Supply Chain Disruptions

Definition and Overview

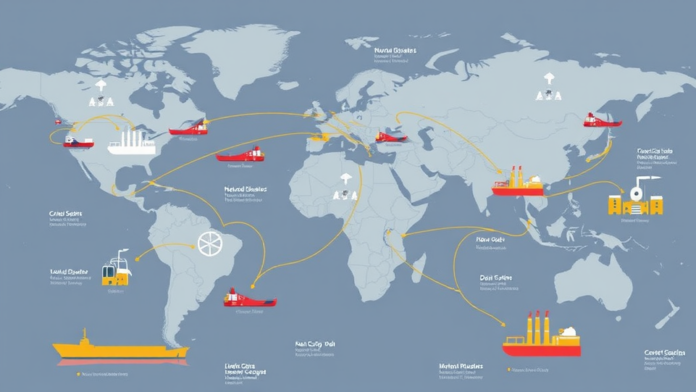

Global supply chain disruptions refer to significant interruptions in the flow of goods and services across international borderc. These disruptions can arise from various factors, including natural disasters, geopolitical tensions, and pandemics. Such events can severely impact businesses, leading to delays and increased costs. It’s a complex issue. Many companies struggle to adapt.

Historical Context and Recent Trends

The historical context of global supply chain disruptions reveals a pattern of increasing vulnerability. Events like the 2008 financial crisis and recent pandemics have exposed weaknesses in logistics. These disruptions have prompted businesses to reassess their strategies. Change is necessary. Adapting to new realities is crucial for survival.

Causes of Supply Chain Disruptions

Natural Disasters and Climate Change

Natural disasters and climate change significantly disrupt supply chains. Events such as hurricanes, floods, and wildfires can halt production and transportation. For instance, the 2020 Atlantic hurricane season caused extensive damage to infrastructure. This led to increased logistics costs and delays. Companies must adapt to these risks. Preparedness is essential for resilience.

Geopolitical Tensions and Trade Policies

Geopolitical tensions and trade policies can severely impact supply chains. Tariffs and trade restrictions create uncertainty in international markets. For example, recent trade wars have led to increased costs for businesses. This results in higher consumer prices. Companies must navigate these complexities carefully. Strategic planning is vital for success.

Impact on Global Trade

Changes in Trade Volumes

Changes in trade volumes directly affect global trade dynamics. Fluctuations can lead to supply shortages and increased prices. For instance, reduced exports from key suppliers disrupt market stability. This creates challenges for businesses relying on consistent supply. Companies must adapt to these shifts. Flexibility is crucial for maintaining competitiveness.

Shifts in Trade Routes and Partnerships

Shifts in trade routes and partnerships significantly influence global trade. Changes in geopolitical landscapes often necessitate new logistics strategies. For example, companies may seek alternative suppliers to mitigate risks. This can lead to increased operational costs. Businesses must evaluate their partnerships carefully. Strategic alliances are essential for resilience.

Sector-Specific Implications

Manufacturing and Production Challenges

Manufacturing and production challenges are increasingly prevalent in today’s economy. Disruptions can lead to decreased output and increased costs. For instance, supply shortages of raw materials can halt production lines. This impacts overall profitability and market competitiveness. Companies must implement agile manufacturing practices. Efficiency is key to overcoming obstacles.

Retail and Consumer Goods Adjustments

Retail and consumer goods sectors face significant adjustments due to supply chain disruptions. These changes can lead to inventory shortages and altered consumer behavior. For example, increased online shopping has shifted demand patterns. Companies must adapt their strategies accordingly. Flexibility is essential for meeting customer needs.

Financial Consequences for Businesses

Increased Costs and Pricing Strategies

Increased costs due to supply chain disruptions significantly impact businesses. Rising expenses can erode profit margins and necessitate price adjustments. For instance, higher raw material costs often lead to increased consumer prices. Companies must carefully evaluate their pricing strategies. Strategic pricing is crucial for maintaining competitiveness.

Cash Flow Management and Financial Planning

Effective cash flow management is essential for business sustainability. Disruptions can lead to unpredictable cash inflows and outflows. Consequently, companies must prioritize financial planning to navigate these challenges. Accurate forecasting is vital for informed decision-making. Maintaining liquidity is crucial for operational stability.

Technological Solutions and Innovations

Supply Chain Management Software

Supply chain management software enhances operational efficiency and visibility. These tools facilitate real-time tracking of inventory and shipments. For example, advanced analytics can predict demand fluctuations. This helps businesses make informed decisions. Companies can streamline processes effectively. Automation reduces manual errors and saves time.

Automation and Robotics in Logistics

Automation and robotics in logistics significantly enhance efficiency. These technologies streamline operations and reduce labor costs. For instance, automated guided vehicles can optimize warehouse workflows. This leads to faster order fulfillment. Companies can improve accuracy and reduce errors. Efficiency is crucial for competitive advantage.

Strategies for Mitigating Risks

Diversification of Suppliers

Diversification of suppliers is essential for risk mitigation. By engaging multiple suppliers, companies can reduce dependency on a single source. This strategy enhances supply chain resilience and flexibility. For example, having alternative suppliers can prevent disruptions. Businesses can maintain consistent production levels. Flexibility is key to managing uncertainties.

Building Resilience in Supply Chains

Building resilience in supply chains requires strategic planning. Companies must assess vulnerabilities and implement proactive measures. For instance, investing in technology can enhance visibility and responsiveness. This allows for quicker adjustments to disruptions. Diversifying suppliers further strengthens supply chain stability. Flexibility is essential for long-term success.

Future Outlook and Predictions

Long-Term Changes in Supply Chain Dynamics

Long-term changes in supply chain dynamics are expected to reshape global markets. Factors such as technological advancements and shifting consumer preferences will drive these transformations. For example, increased automation may enhance efficiency and reduce costs. Companies must adapt to remain competitive. Strategic foresight is essential for navigating future challenges.

Preparing for Future Disruptions

Preparing for future disruptions requires proactive strategies. Companies should conduct regular risk assessments to identify vulnerabilities. This enables them to develop contingency plans effectively. Investing in technology can enhance responsiveness and adaptability. Flexibility is crucial for maintaining operational continuity. Strategic planning is essential for long-term success.